Innovotek -News & BLOG

A blog about the news of the latest technology developments, breaking technology news, Innovotek Latest news and information tutorials on how to.

System-level design of mixed-signal ASICs using Simulink: Efficient transitions to EDA environments

- Font size: Larger Smaller

- Hits: 6574

- 0 Comments

- Subscribe to this entry

- Bookmark

Abstract

Abstract

Simulink models are used as executable specifications in commonly used design flows for mixed-signal ASICs. Based on these specifications, analog and digital components are directly implemented in mixed-signal design environments. This step constitutes a large leap of abstraction. In this work, we address this aspect by showing and discussing an approach for automated transitions from Simulink models representing analog and digital components to HDL descriptions using HDL Coder. On the one hand, we translate analog Simulink components into continuous-value discrete-time HDL descriptions that can serve as reference behavioral models in the mixed-signal design environment. On the other hand, for digital Simulink components, we developed optimizations for Simulink models in order to achieve resource-efficient HDL descriptions. Both solutions in the analog and digital domain were integrated into Simulink Model Advisor. An evaluation of the presented design flow, as applied to an automotive hardware design, is shown.

Introduction

Electronic Control Units (ECUs) in the field of automotive electronics generally interact with the physical environment by using sensors and actuators. Thereby, mixed-signal ASICs (Application Specific Integrated Circuits) are needed as an interface between microcontrollers and sensors as well as actuators. In this work, we focus on ASICs connected to sensors, whereby the sensor is often enclosed with the ASIC into a system-in-package (SiP). In the most general case, mixed-signal ASICs consist of analog, non-programmable digital and programmable digital components.

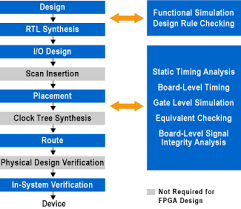

The increasing integration density of ASICs allows more and more functionality, which leads to more complex ASIC designs. These require a holistic view on a high abstraction level at the beginning of the design. Therefore, a system-level (SL) design methodology is needed, where all ASIC components and the associated sensor are modeled in a common SL design environment. In standard flows, the design starts by developing an SL model that serves as executable functional specification. Based on this specification, the particular ASIC components are designed on implementation level (IL) isolated from the overall system and without any reuse of the design effort performed at SL. The isolation between SL and IL constitutes a gap in the design flow, which leads to redundant implementation efforts and consistency problems between SL and IL. Furthermore, the isolation of components from the overall system during implementation leads to lost optimization potential. That is why in (1), we proposed a seamless SL design methodology, which uses automated transitions from SL to IL models in order to reduce the effort of design transfer between SL and IL (see Figure 1).

Assisted refinement of SL model components with respect to the surrounding system and automated top-down transitions from SL to IL are suggested in order to transfer design effort from SL to IL. SL and IL are defined as follows: At SL, the whole ASIC and its connected sensor is considered in a common design environment, whereby the ASIC SL model consists of analog, digital and software partitions. Then again, there are IL models, which describe a system component of a single domain in its domain-specific language and design environment. IL models are later refined down to a physical implementation either in a manual or an automated design flow that depends on the particular domain. After we provided approaches for top-down transitions from MATLAB/Simulink both in the digital and the analog domain (see (2) and (3)), in this article, we present the combination of both approaches and their application to an automotive mixed-signal hardware design.

System-level design environment: Simulink

For heterogeneous systems, SL design environments have to support the description of system components from different domains. We use MATLAB/Simulink (see (4)) as SL design environment, which constitutes a de facto standard for signal processing design in automotive applications.

Simulink is a graphical multi-domain design environment and supports multiple models of computation like continuous-time, discrete-time and electrical modeling. Thereby, Simulink models can include blocks from the Simulink library as well as blocks described in different languages like MATLAB, Stateflow and Simscape, and programming languages like C and C++. Simulink library blocks allow the description of analog circuits both as continuous-time and discrete-time signal-flow models. Simscape offers the possibility to model systems as physical networks. It can be used for the modeling and simulation of electrical systems whereby these systems obey Kirchhoff's laws. With Simscape, Simulink is also suited for the description of analog components and sensors as electrical and mechanical systems.