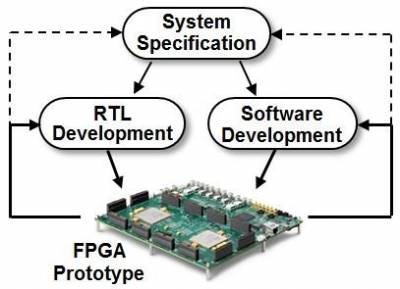

Today, a lot of the system-on-chip (SoC) designs depend on Field-Programmable Gate Arrays (FPGAs) as a way to accelerate verification, early start of software development and validate the whole system before committing to silicon. This is done primarily to meet time-to-market demands. Today's FPGAs have the capability to contain a complex and large system-level design. However, in some cases, there is a requirement for these designs to be partitioned among several FPGAs for validation or prototyping. But, splitting the design into several FPGAs can create various partitioning issues, especially for relatively large designs with complex connectivity. These issues could possibly be circumvented if certain guidelines are followed. This paper talks about the general partitioning challenges and the guidelines that can be followed to get past these issues.

Today, a lot of the system-on-chip (SoC) designs depend on Field-Programmable Gate Arrays (FPGAs) as a way to accelerate verification, early start of software development and validate the whole system before committing to silicon. This is done primarily to meet time-to-market demands. Today's FPGAs have the capability to contain a complex and large system-level design. However, in some cases, there is a requirement for these designs to be partitioned among several FPGAs for validation or prototyping. But, splitting the design into several FPGAs can create various partitioning issues, especially for relatively large designs with complex connectivity. These issues could possibly be circumvented if certain guidelines are followed. This paper talks about the general partitioning challenges and the guidelines that can be followed to get past these issues.

Need For Partitioning:

As devices being prototyped on FPGAs are getting larger, following good design practices become important for all design flows. Adhering to recommended synchronous design practices makes designs more robust and easier to debug. Using an incremental compilation flow adds additional steps and requirements, but can provide significant benefits in design productivity by preserving the performance of critical blocks and reducing compilation time.

...

Implantable medical devices have been around for decades. Early on, most of the established applications for medical devices focused on cardiac rhythm management. Such devices were used to treat irregular heart rhythms, such as bradycardia (beating too slowly) or tachycardia (beating too fast).

Implantable medical devices have been around for decades. Early on, most of the established applications for medical devices focused on cardiac rhythm management. Such devices were used to treat irregular heart rhythms, such as bradycardia (beating too slowly) or tachycardia (beating too fast).